Data of Company

| Name of Company | : | AMPACET (THAILAND) CO LTD |

| Company Type | : | Ltd |

| Year of Established | : | 1937 |

| Line of Business | : | Manufacturer |

| Business Type | : | Packaging Raw Materials |

| Member of Association | : | IPF |

Head Office

| Address | : | Indonesia Representative Office The Plaza Office Tower, 41st Floor Jl. MH. Thamrin, Kav. 28-30 |

| City | : | Jakarta Pusat |

| Province | : | DKI Jakarta |

| Zip Code | : | 10350 |

| Phone | : | 081585381737 |

| : | Dessy.Mutiara@ampacet.com |

Contact Person

| Marketing Manager | : |

Dessy Mutiara

081585381737 Dessy.Mutiara@ampacet.com |

Products Data

| Category | : | Packaging Component & Auxiliary |

| Sub-Category | : | Additive, Anti Corrosion, Masterbatch |

Artikel

Odor Absorbing Additive Masterbatch for Post-Consumer Plastics Recycling

Introduction

Masterbatch are used by plastics processors to ensure good dispersion of additives in polymer matrix, especially when additives are needed in low concentration. The additives are pre-dispersed in a resin carrier so that processors can easily let-down into their resin during processing.

Circular economy has become increasingly important, post-consumer plastic packaging wastes are being recycled into new articles. Post-consumer recycled plastics often show a strong smell due to the presence of contaminants or residual contents (e.g. food, detergent, inks, adhesives…) degrading during the recycling process.

Such undesirable smell is usually limiting the amount of recycled plastic that can be used in new plastic articles as affecting consumers’ perception of the product’s and brand’s quality.

Benefits

To support plastic industry, brand-owners and converters to achieve and even surpass these circular economy targets, wide range of innovative products have been developed along with services, including odor absorbing masterbatch portfolio.

Properly formulated odor absorbing masterbatch are powerful absorbing wide spectrum of odor, designed for use with a broad range of recycled polymers. They minimize odors of post-consumer recycled material allowing converters to boost packaging recycled content, improving their circular economy achievements.

Examples of end products made of post-consumer plastics recyclate are packaging bottles for home care and personal care, plastic sheet.

Performance

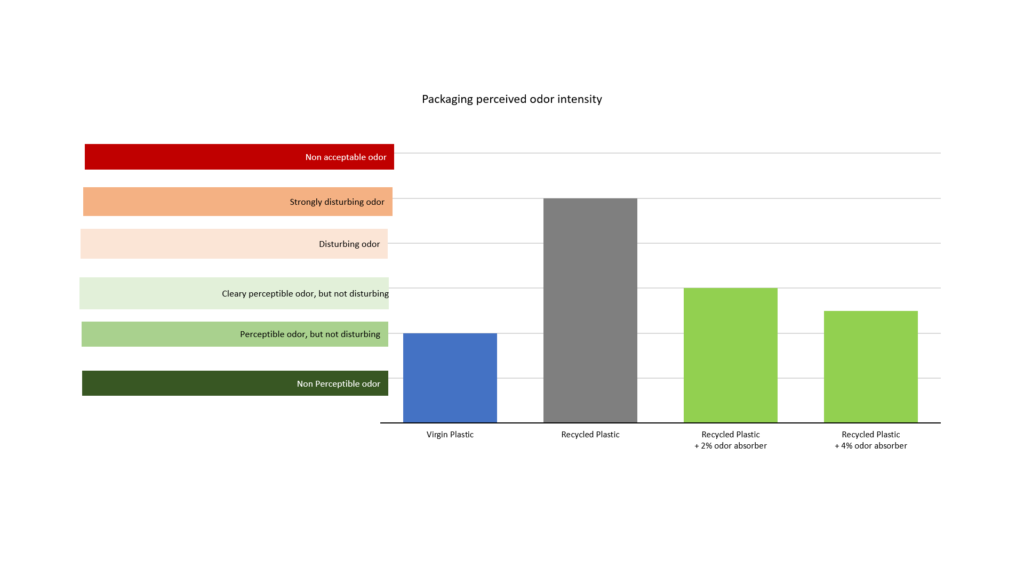

The odor absorber masterbatch was added to plastic packaging made out of odorous post-consumer recycled polymer (PCR). Performance on smell reduction was evaluated by a panelist of testers, using the odor perception classification.

The effect of odor absorber masterbatch on smell intensity of packaging[1] is summarized in Figure 1.

Figure 1: Perceived odor intensity of packaging made out of odorous PCR1

[1] The test method used is inspired from automotive norm VDA270 and adapted to post-consumer recycled materials

2 Odor absorber masterbatch addition rate and final smell perception of packaging depend on the initial smell intensity of PCR used

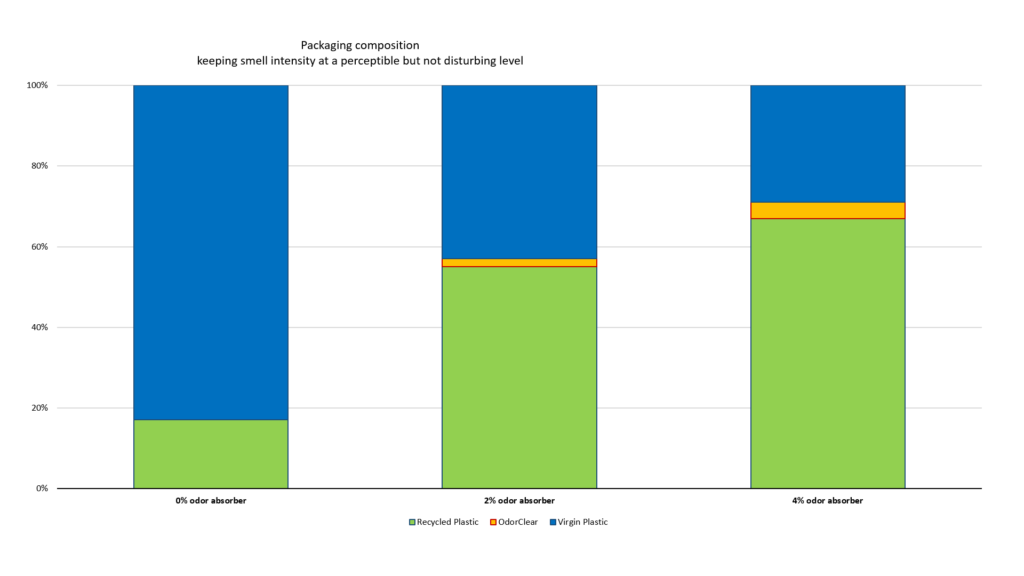

The odor absorber allows to increase the ratio of post-consumer recycled polymer (PCR) in a post-consumer/virgin resins blend while keeping the smell intensity at a perceptible but not disturbing level, as illustrated in Figure 2.

Figure 2: Effect of odor absorber masterbatch PCR / Virgin resins blends ratio

Adding odor absorber masterbatch to a post-consumer/virgin resins blend allows to increase the ratio of recycled polymer in the end product while keeping smell at the desired level. It allows to boost the recycled content of packaging and support circular economy targets.

The recommended level of odor absorber masterbatch to be added depends on the quality and smell intensity of the post-consumer recycled material used, but will typically range between 2% and 6%.

Odor absorber masterbatch can be used in combination with other solutions for circular economy to minimize problems linked to thermal degradation, color or poor uniformity often faced when using high quantities of recycled material.

It is up to every plastic processor to assess the maximum concentration of post-consumer recycled material allowed in its end-product, in line with mechanical properties as well as with other end-use requirements.

Tests with different sources of post-consumer recycled polymers show the odour absorber masterbatch is efficient in absorbing a broader range of molecules and smells.

Value Proposition

Wide spectrum odor absorbing masterbatch portfolio have been developed, allowing recyclers and converters to:

- Minimize odors of post-consumer recycled materials, beyond conventional deodorizing process

- Boost packaging recycled content while keeping the perceived odor at an acceptable level

- Achieve recycled content requirements imposed by legislations or targeted by brand-owners

- Support overall circular economy initiatives

Odor absorber masterbatch from Ampacet are marketed as OdorClearTM, other solutions available for circular economy are ThermProtectTM , Blue EdgeTM, ReViveTM, etc.

For more information on Ampacet portfolio, recommendations of use and complete Regulatory Status, contact your Ampacet Sales Representative or visit www.ampacet.com